We don't wait to see what the future brings. We shape it ourselves.

We are guided by the ideas and requirements of our customers in terms of technology and product. Combined with the excellent expertise of our employees, this results in innovative, forward-looking processes.

Current projects

2024-2027: SEMECO - B4: Mobile detection of microperfusion (“MikroFlow”)

The aim of the project is the design and implementation of a compact, energy-efficient measuring system for the diagnosis of impaired microcirculation (blood flow in organs and tissues) and the early detection of signs of decompensation in the event of disturbance of the intravascular fluid balance while respecting medical safety standards and the applicable data protection requirements. Decoupled measurement of microcirculation is important to better understand the relationship between macrocirculation and thus to derive appropriate treatment measures for patients. Schmietex Engineering GmbH offers a necessary component for the technical implementation in a textile environment with a mechatronic system, which presses the sensor against the body with the required contact pressure during the measurement and releases it again after a defined time interval.

2023-2026: Component and technology development for the digitalised and process-monitored production of complex closing wires with the associated "INNO-QS-SDK" QA system

The aim of this project is to develop a fully automated and functional manufacturing process for the production of closing wires with integrated process and quality monitoring. The aims are to reduce waste and energy consumption, conserve resources and increase productivity. Existing challenges in locking wire production are to be investigated and solved with the help of innovative optical monitoring as part of this research project.

2023-2024: Study on the development of a new type of weft laying system for filament-reinforced adhesive tapes

In order to achieve the goal of developing a new type of weft laying system for thread-reinforced tapes, packaging materials and adhesive tapes are systematized. Technologies and their requirements are then systematized.

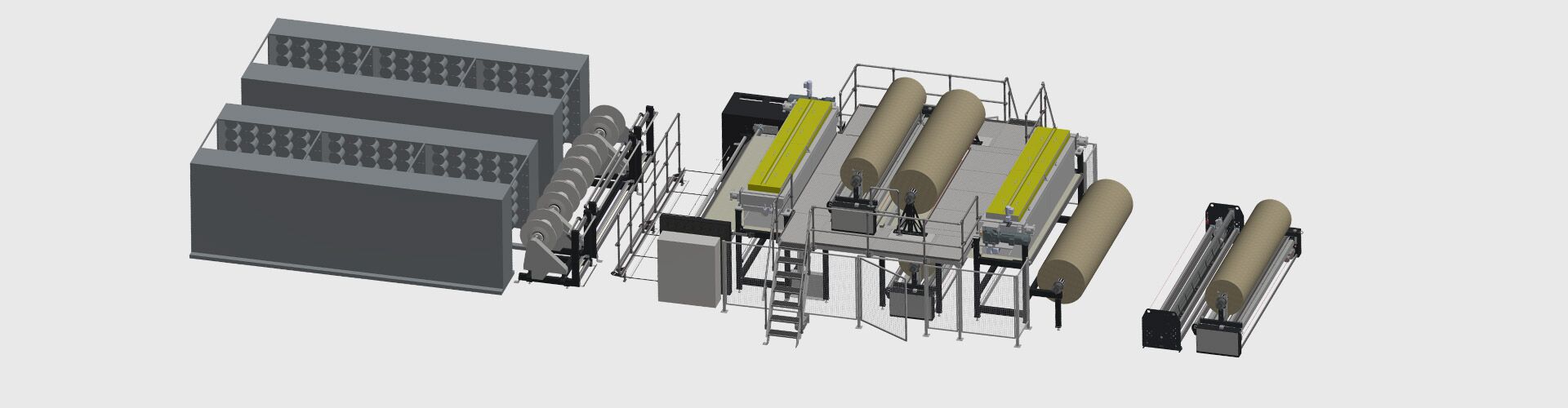

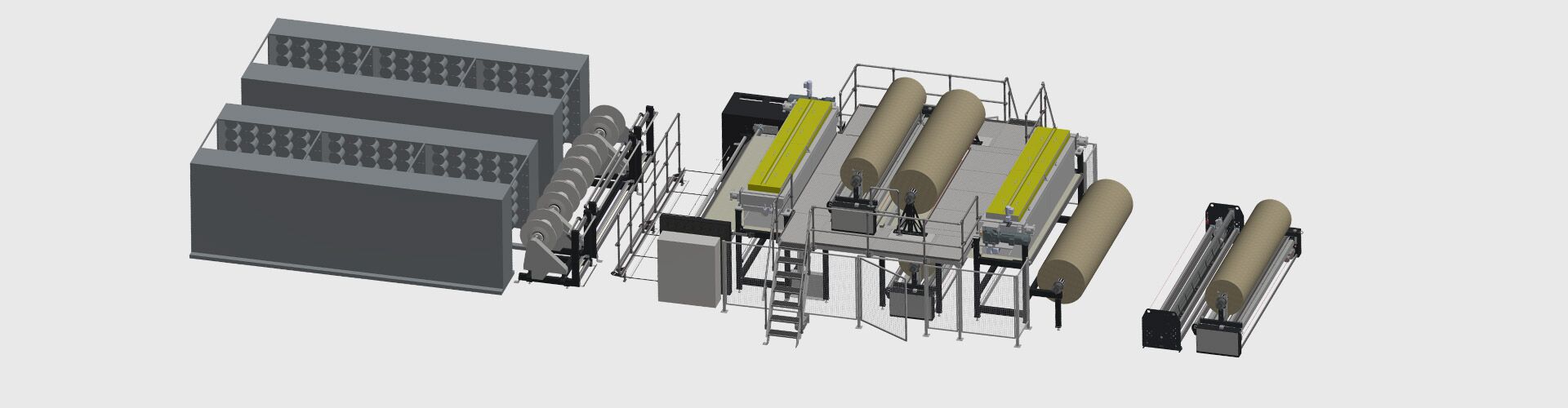

2019-2022: effiLoad - Development of a research function pattern plant for the continuous production of near-net-shape, load-path-compliant and waste-reduced preforms for high-performance components

The aim of the project is to develop the effiLoad overall system and the modular overall concept of the basic machine to accommodate the modules for tape laying and the hybrid roving fixation of the basic system. In addition, research function samples are manufactured on the machine.

2020-2021: Study on the development of a test device for determining the puncture force in technical textiles

The objective of the innovation award is the development of a technology study and conception of a testing device for testing technical textiles and determining the penetration force. First of all, a systematisation of the already existing testing devices is to be developed. Furthermore, the standards that already deal with this topic are to be systematised and evaluated. Subsequently, a test device is to be designed with the help of which the testing of technical textiles and the determination of the penetration force is possible. Deviating tests or tests that are not possible on the test device are to be explicitly listed.